Case Studies | SonicAnalyst™

Energy Focus | A Changing Energy Landscape

12 April, 2018Case Studies | SonicAnalyst™

Our team is pleased to release two new Case Studies for our SonicAnalyst™ TCP & Frac Event Monitor.

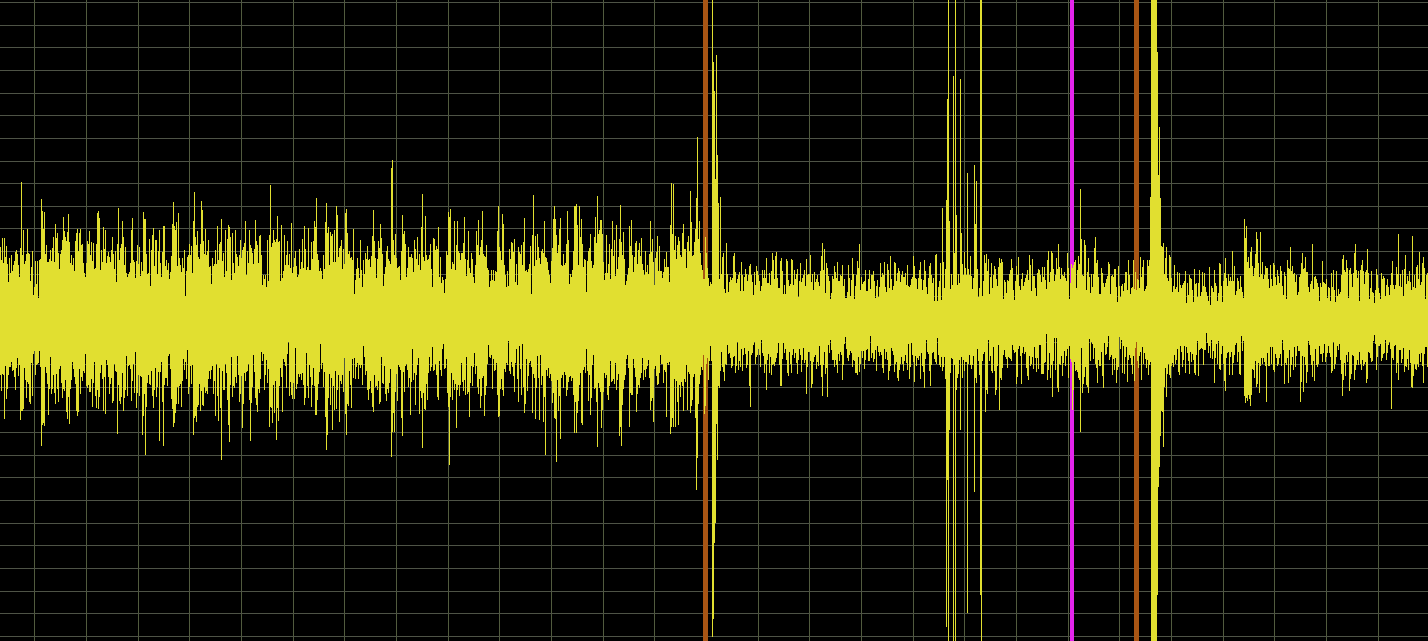

Case Study 1: During a SonicAnalyst™ deployment, the operator was able to identify a missed ball launch at surface that would have resulted in a sleeve not shifting, and a frac not being diverted as required. They were able to reset the frac equipment and complete a successful frac after the fault had been flagged by technology.

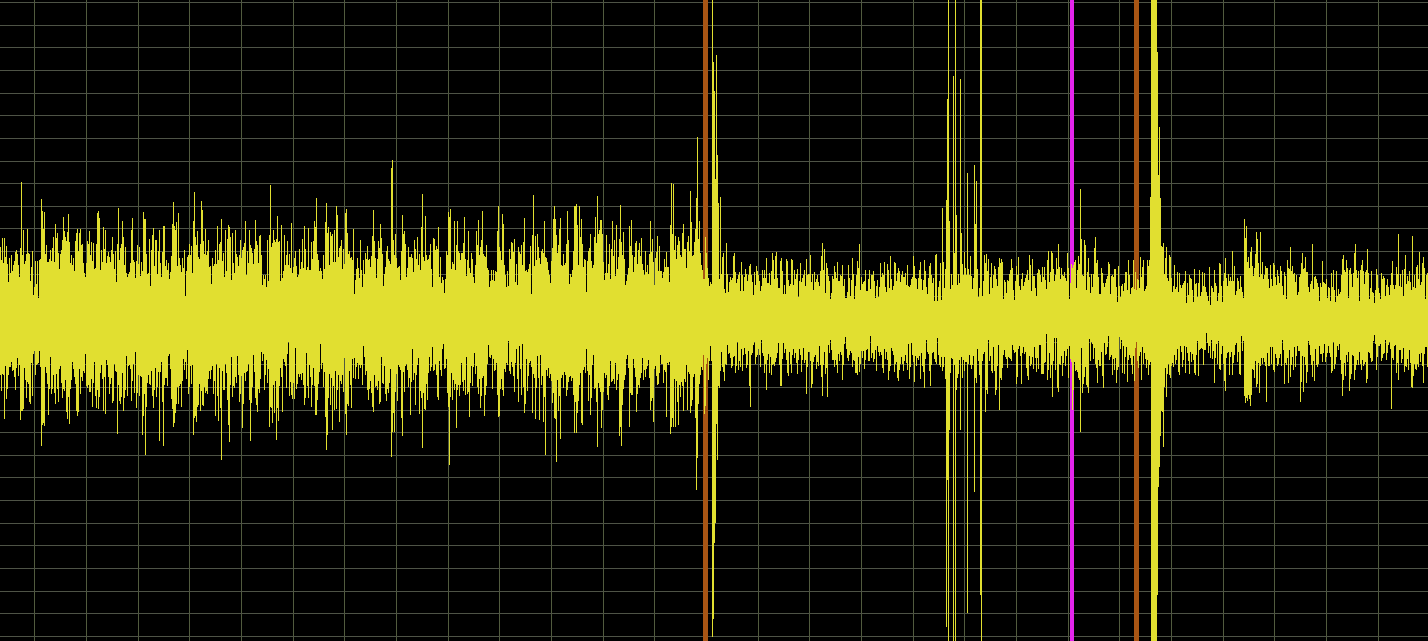

Case Study 2: The graph presents averaged noise amplitude data together with the max and min torque readings observed at the surface during a few minutes every hour. Data gathered by the SonicAnalyst™ correlated with rod string torque, and four distinct noise/torque peaks were observed before the rod string broke.

Click here to learn more: Product Page