SUSTAINABILITY & CARBON FOOTPRINT

At Acoustic Data, we take our responsibility to the Planet seriously, and our Green philosophy is proudly applied from manufacture through to deployment to reduce our use of single-use plastics and CO2 footprint.

We start with simple measures such as requesting our suppliers to wrap our inwards parts in biodegradable waxed paper, and similarly, we have a no single-use plastics packaging philosophy; our outbound packages are made of wood and cardboard.

Our equipment is designed to be produced in an environmentally efficient manner, with as little machining and waste as possible. This approach synergistically results in a low manufacturing cost and robust designs. The flow-on is our ability to introduce efficient, accurate, low-cost instrumentation to optimise economic production of the wells deployed in a less environmentally disturbing approach than drilling new wells.

Our SonicGauge™ equipment is ultra-energy efficient and can be deployed over long periods in wells without intervention. Our battery-powered solutions are extremely small compared with our competitors, producing several years of performance from just four cells. Similarly, our Barracuda™ ElectroSET™ is powered by a small stack of rechargeable batteries. Fewer cells, less waste coupled with responsible disposal yielding less pollution.

With rising CO2 levels in our atmosphere, we are doing our bit to provide a low CO2 footprint solution for subsurface data acquisition. Our SonicGauge™ is a compact, lightweight and simple system that can be hand carried to wellsite and then hand deployed in the well. This results in less transport fuel burden, no dedicated trucks and cranes, fewer transport personnel and storage overhead—a very low carbon footprint from workshop to wellbore.

CARBON EMISSIONS REPORT

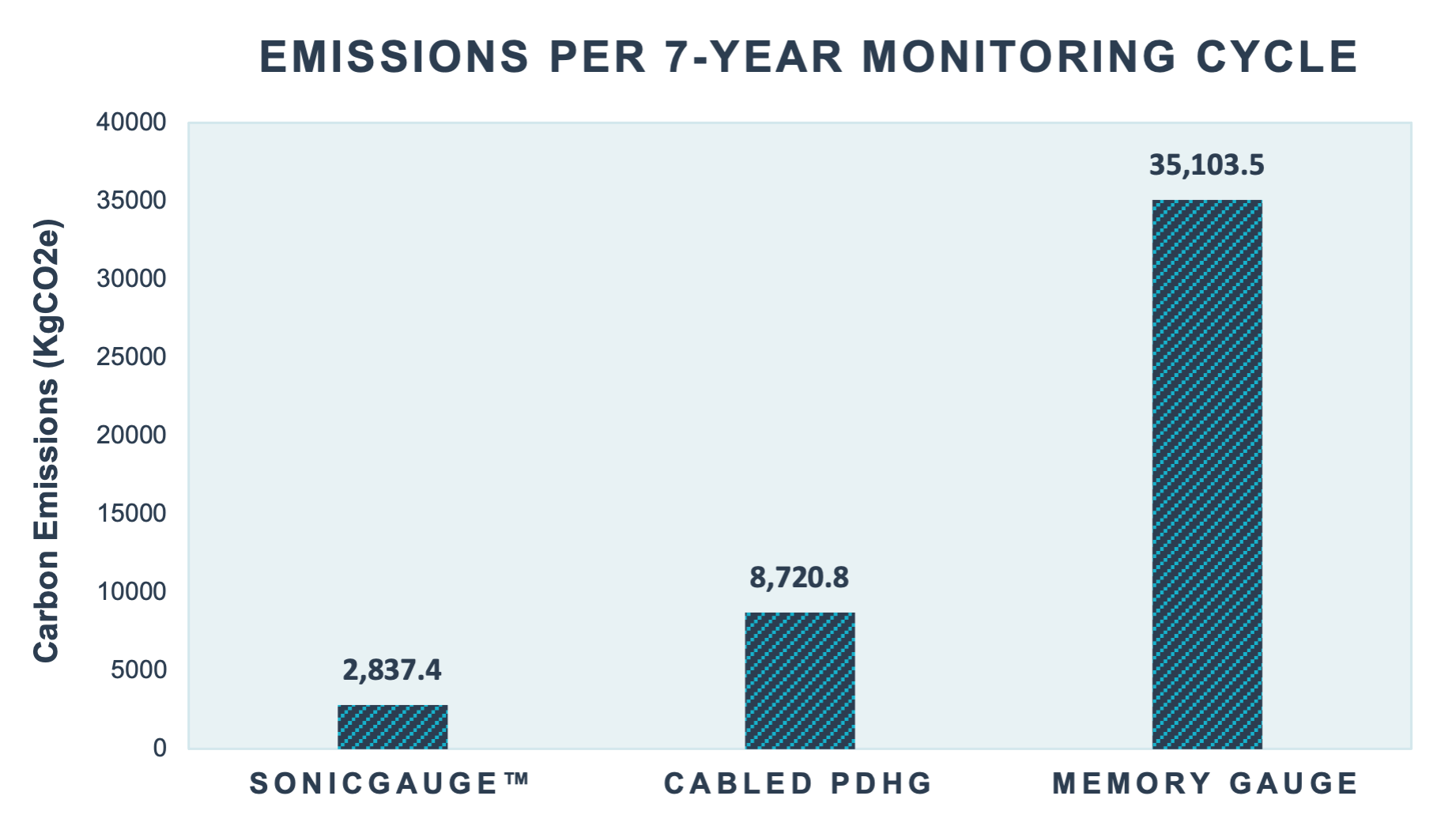

This report was commissioned to demonstrate that Acoustic Data’s SonicGauge System has a significantly smaller GHG footprint than its competitors and thereby assists operators in reducing their GHG emissions. The analysis calculates the effective GHG emissions of three downhole pressure monitoring systems over seven years in a typical 2000m onshore oil well. Calculations consider manpower, logistics and operational requirements from manufacture to disposal.

Based on the data gathered from commonly used oil and gas technologies — represented in the graph below — calculations were carried out modelling a 7-year production monitoring period, yielding the following summations from the process:

• Emissions attributed to the use of SonicGauge total 2,837 KgCO2e.

• Average (median) emissions for the other two production monitoring options total 21,912.1 KgCO2e.

• SonicGauge monitoring provides a median emissions reduction over its competitors of 19,074.1 KgCO2e.

• An average reduction in GHG emissions of 87%.