CASE STUDY 1

HYDRAULIC FRACTURE MONITORING

Client

North American Operator - Canada

Technology

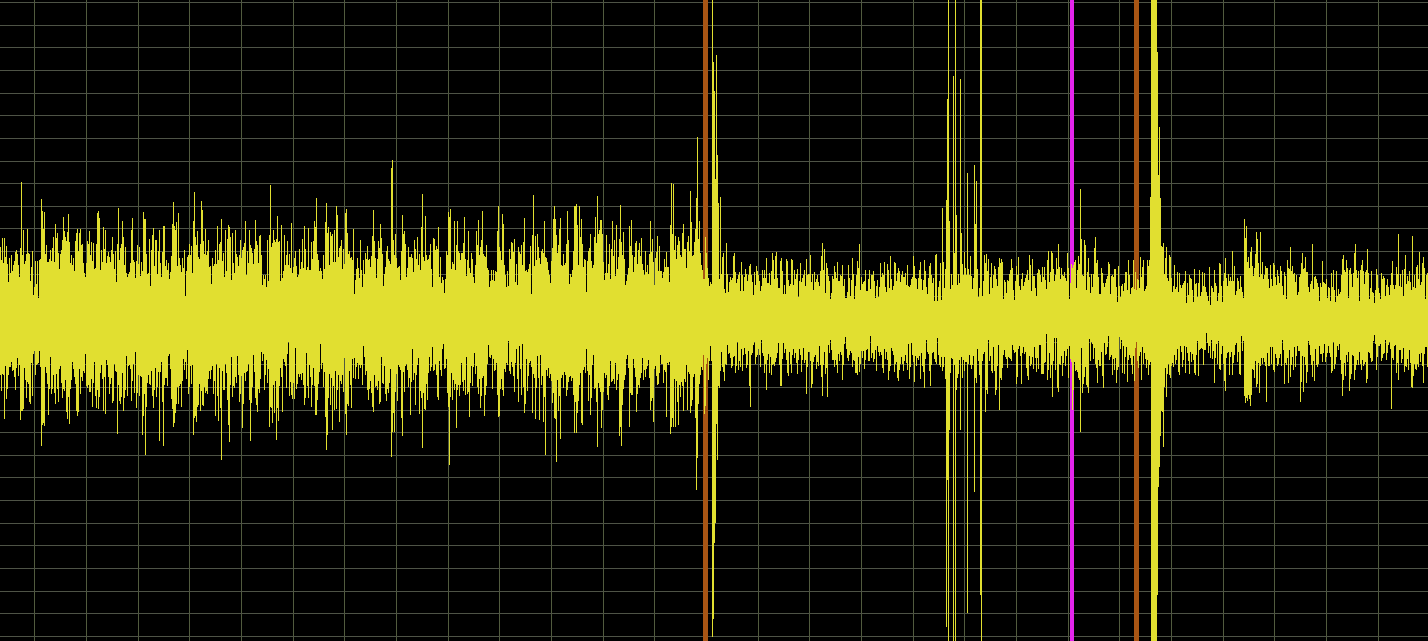

SonicAnalyst™ TCP & Frac Event Monitor

Challenge

Monitor Frac Diversion

Outcome

During a SonicAnalyst™ deployment, the operator was able to identify a missed ball launch at surface that would have resulted in a sleeve not shifting and a frac not being diverted as required. They were able to reset the frac equipment and complete a successful frac after the fault had been flagged by the SonicAnalyst™.

Solution

The operator estimated that the SonicAnalyst™ information saved them US$300,000 in failed frac costs.