WELL ABANDONMENT & BARRIER VERIFICATION

When conducting well suspension operations, ensuring the long-term pressure integrity of the barrier is critical. Typically, the barrier is leak-tested by pressurising from above shortly after installation. However, these tests do not allow monitoring of the differential pressure across the barrier or any means of monitoring medium- or long-term hydraulic integrity.

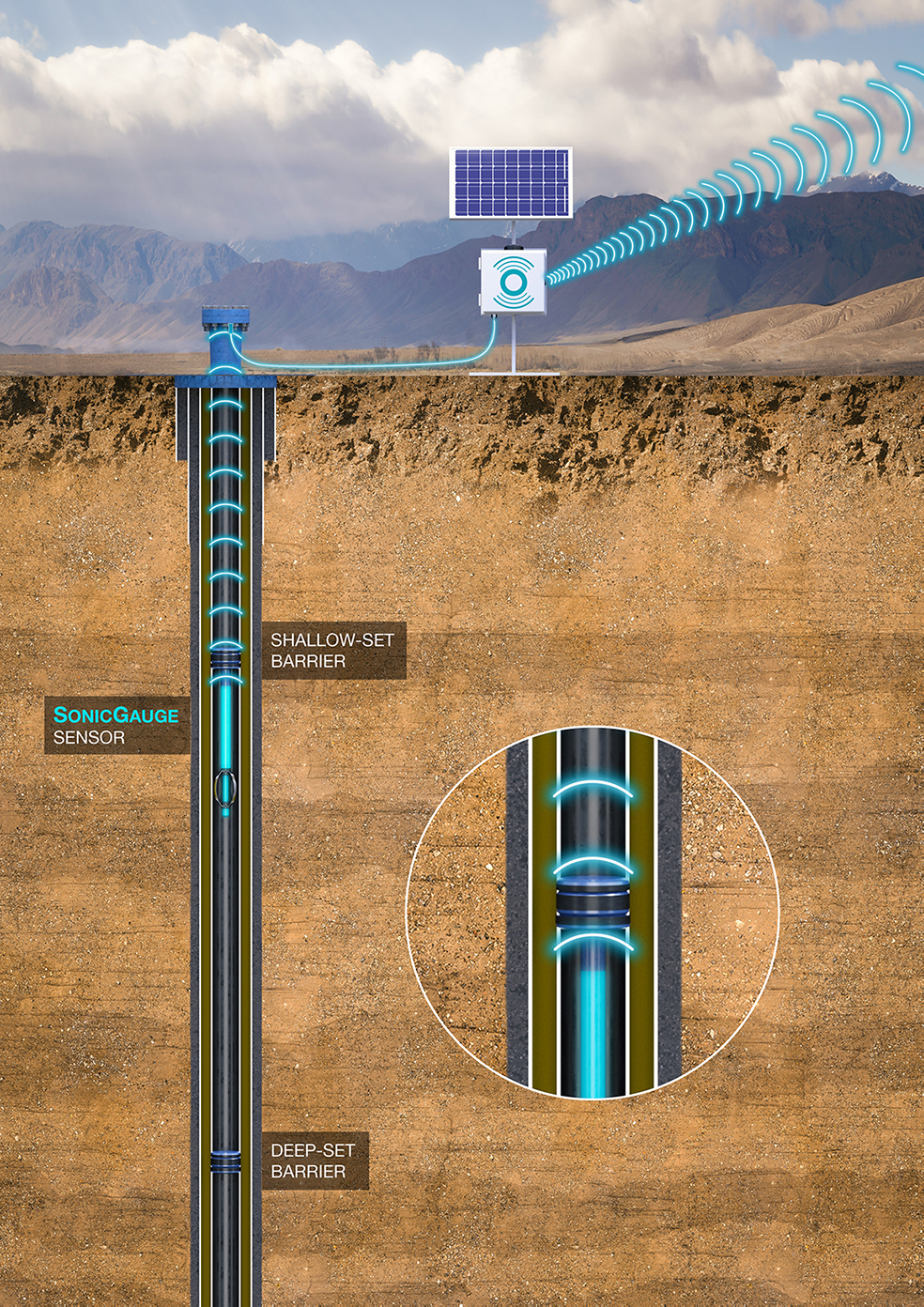

Acoustic Data’s SonicGauge™ Barrier Verification System can be deployed with mechanical plugs, storm packer, inflatable packers or metal barriers to instrument both the initial pressure testing and provide ongoing pressure measurement from both above and below the plug. The system can be configured to provide real-time data at surface for up to eight years due to the technology operating on an ultra-low energy budget.

The SonicGauge can be deployed on the bottom of a third-party plug or independently on the Barracuda™ HEX-Hanger™ (high expansion gauge hanger). A corresponding SonicRepeater station with an onboard pressure transducer is often deployed on a HEX-Hanger above the plug to record pressure above the barrier. It also records the pressure data transmitted by the SonicGauge from under the barrier. Both sets of data are sent to surface in real-time. If real-time reporting is not required, the SonicRepeater station can be retrieved by slickline from time to time to analyse the historical data saved to onboard memory.

The Barracuda™ product line also includes a HEX-Retainer™; a high expansion basket retainer that can be deployed by slickline through 2-7/8” tubing and set in up to 9-5/8” casing size. It is used to retain cement, frac sand, metal alloy, such as bismuth-tin (BiSn), and other plug materials.