SONICGAUGETM BVS

BARRIER VERIFICATION SYSTEM

- 170+ years of accumulated downhole monitoring time globally (350+ installations)

- Can provide surface-read-out (SRO) of downhole data without intervention

- Deployed on the bottom of a plug or packer with no additional rig time (single run)

- Fully wireless: no wellhead penetrations, downhole cables, or connectors required

OVERVIEW

The patented SonicGauge™ Barrier Verification System (SG-BVS) is the state-of-the-art two-way (duplex) acoustic telemetry system that measures and wirelessly transmits wellbore pressure to surface in real-time to verify the integrity of a downhole barrier, such as a retrievable bridge plug, storm packer or inflatable packer.

When conducting well-plugging operations, the long-term pressure integrity of the barrier is critical. Typically, the barrier is inflow tested from below, or pressure is applied from above to ensure the plug is holding pressure. However, these tests are carried out shortly after the plug is deployed and, as such, do not offer ongoing assurance of barrier integrity.

The SonicGauge BVS can be deployed with mechanical plugs, storm packers, inflatable packers or metal barriers to monitor the initial pressure test and provide ongoing pressure measurement to confirm continued well isolation for up to eight years.

APPLICATIONS

- Continuous Mechanical Barrier Verification Monitoring

- Long-Term Well Suspension Monitoring

- Pre-Abandonment Well Plugging Integrity Monitoring

- Temporary Zonal Isolation Monitoring

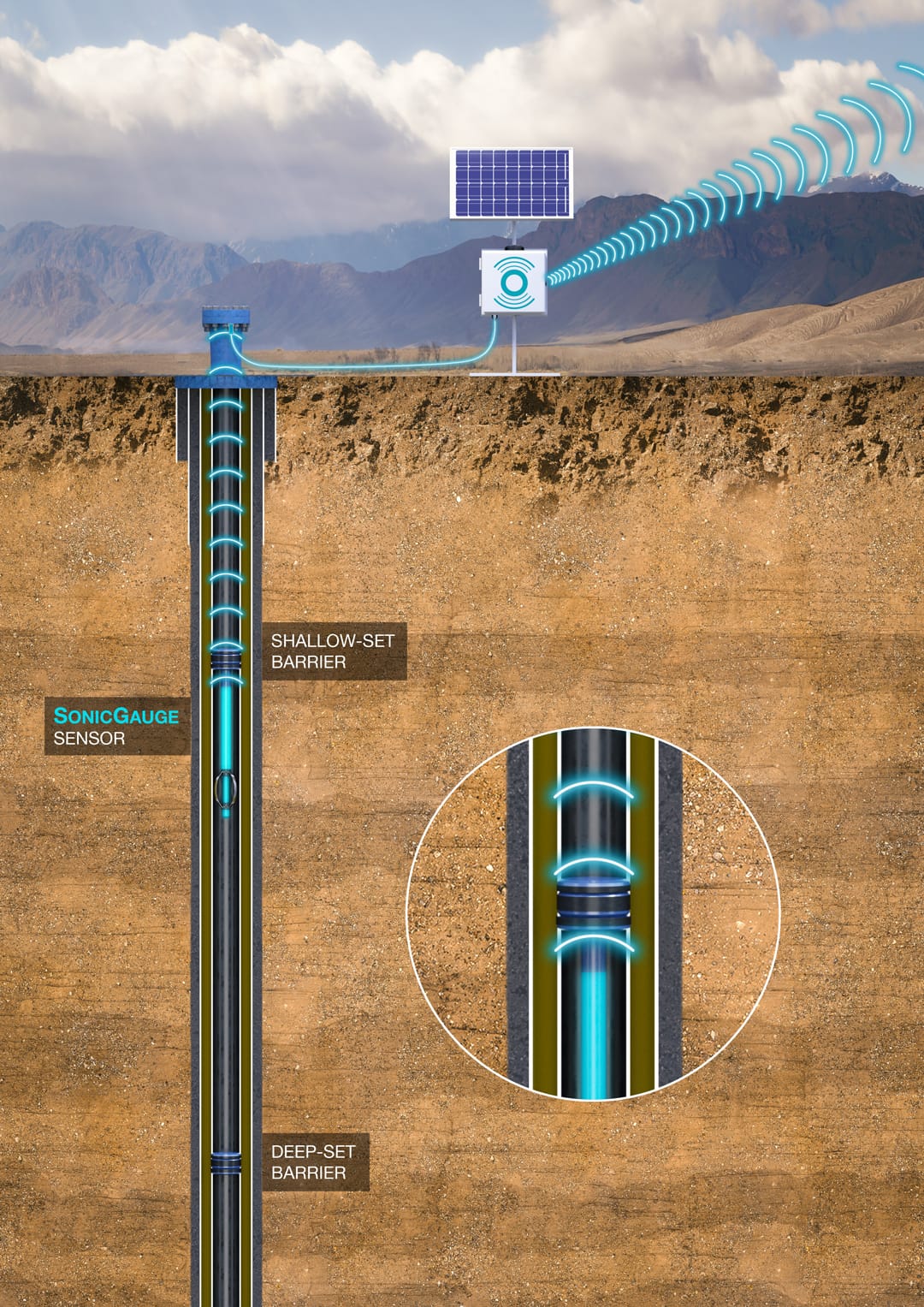

- Shallow or Deep-Set Monitoring

INTEGRATION WITH

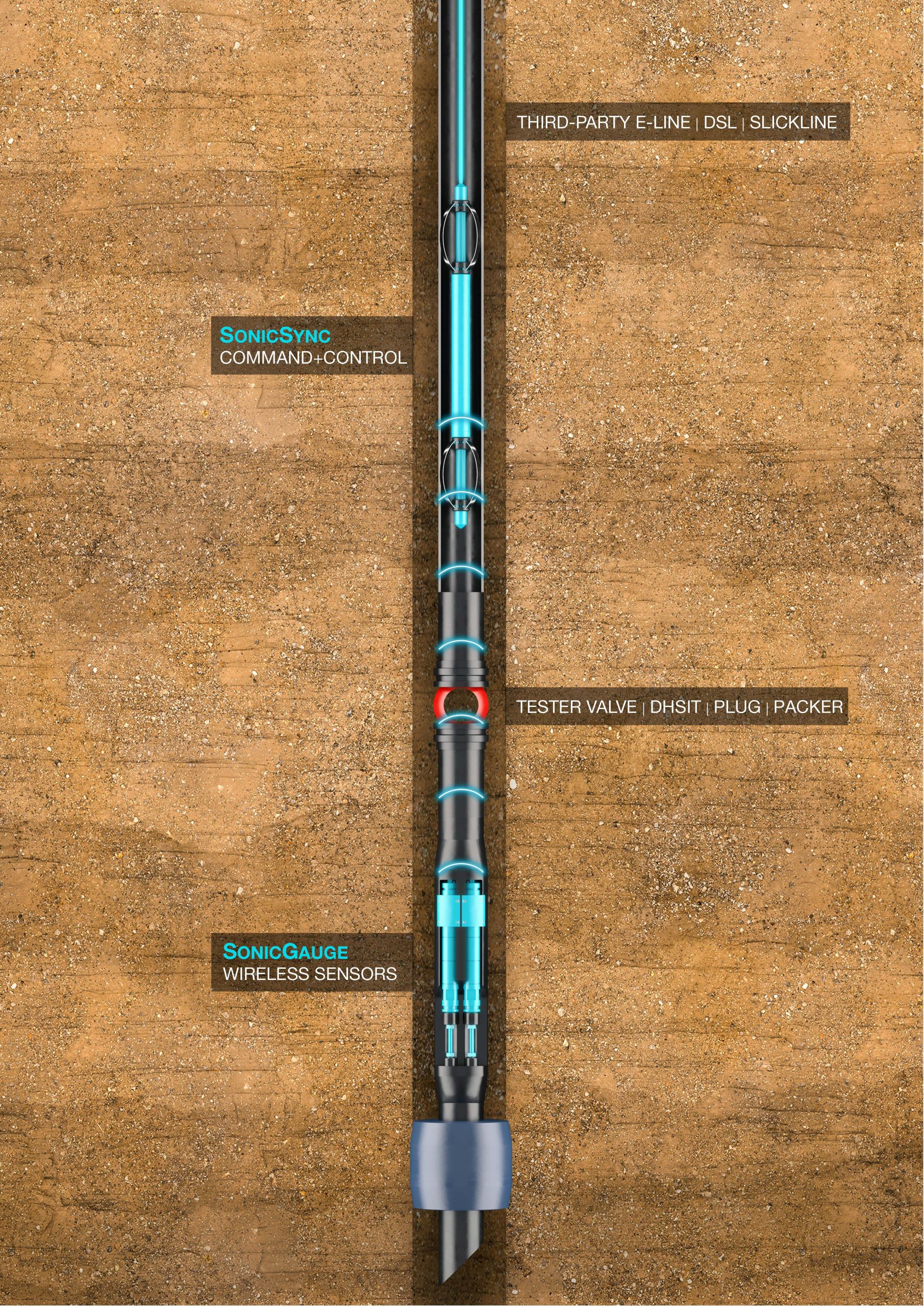

DSL, E-LINE & SLICKLINE

Leveraging over a decade of well testing and multi-year reservoir monitoring via wireless communication, Acoustic Data can interrogate and reprogram the SonicGauge BVS via the SonicSync™ Command+Control Platform directly from surface or via a slimline well intervention tool.

SONICSYNC™ WELLHEAD MODEM

A command tool driven by a laptop interface is temporarily attached to the wellhead/tubing hanger flange to send acoustic commands downhole to activate, control or check the status and diagnostics of downhole equipment. Depending on the depth, SonicRepeater stations are deployed along the tubing to boost the range of the system—effectively providing an unlimited transmission distance.

SONICSYNC™ INTERVENTION MODEM

A short-hop wireless downhole communication system deployed via slickline (pre-programmed, data to memory) or wireline/digital slickline (real-time commands sent from surface, real-time data sent to surface), which can interrogate SonicGauge sensors located below barriers, such as a retrievable bridge plug, hurricane packer, tester valve or DHSIT.

SONICREPEATER PICK-UP

Alternatively, a SonicRepeater tool can be deployed on the Barracuda HEX-Hanger above the barrier to receive, decode and store the downhole data sent from the SonicGauge sensor below the barrier. Periodically, this tool can be retrieved via slickline to download the downhole data before being reinstalled for continued data acquisition.

SURFACE OPTIONS

SPECIFICATIONS

| SONICGAUGE™ BARRIER VERIFICATION SYSTEM | |

|---|---|

| Real-Time Surface Read-Out (SRO) | Yes (1 Second to Hourly Data) |

| Communication Type | Duplex via SonicSync™ (Two-Way Mesh Network) |

| Transmission Distance | Unlimited with SonicRepeater Stations |

| Downhole Sensor | Piezo | Quartz |

| Multi-Sensor Configuration | Above & Below Barrier |

| Temperature Rating (Max.) | 150°C (302°F) |

| Pressure Rating Options (Max.) | 10,000 | 15,000 | 25,000psi |

| Length | 1,300 – 1,800mm (51.2 – 70.9") |

| Diameter | 33.4mm (1.31") |

| Material | Super Duplex | Inconel |

| Battery Life | Up to 8 Years (20% Safety Factor) |

CONTACT US

Have a question or want to book a demo?Our team of experts are on hand to help.