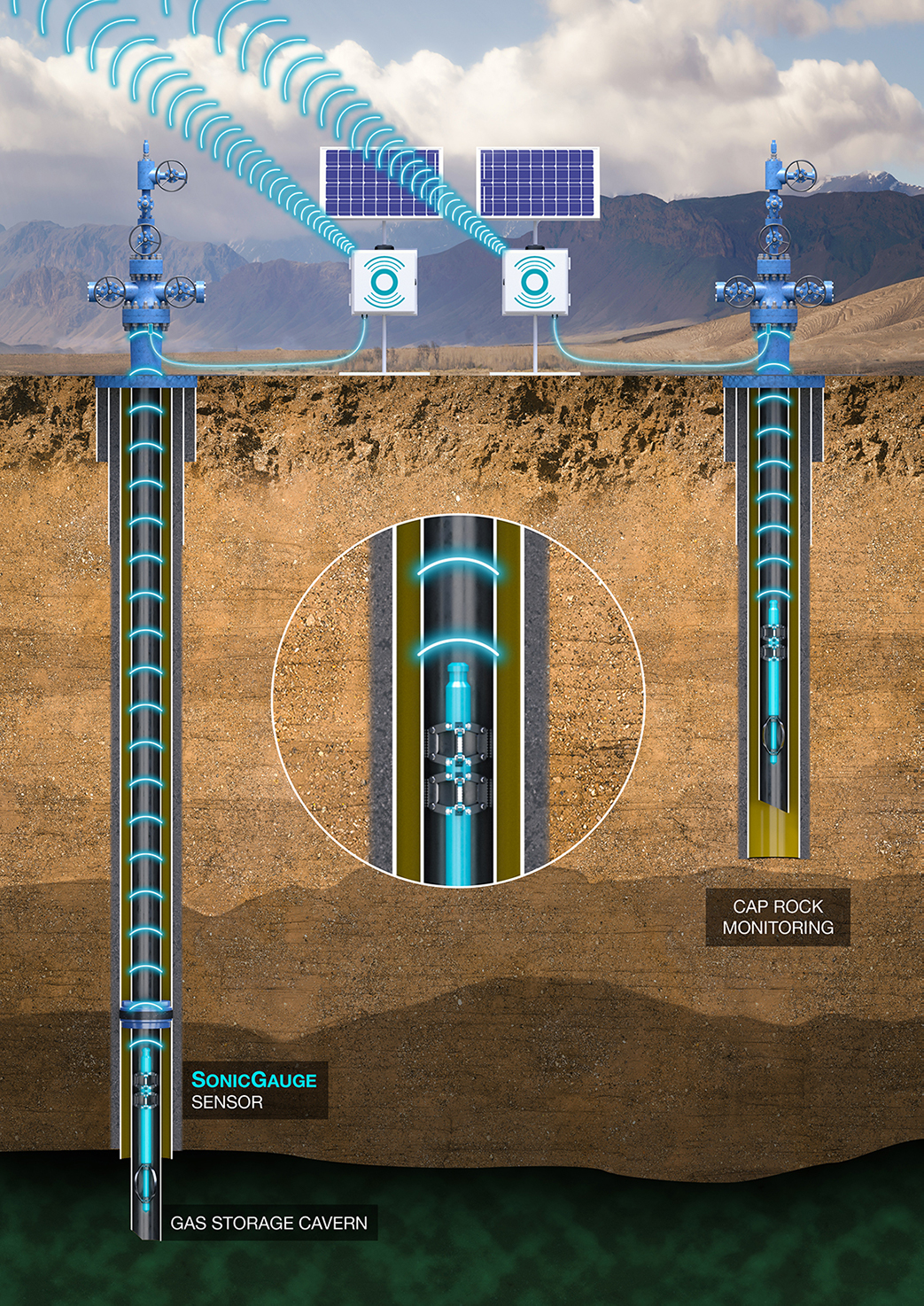

UNDERGROUND ENERGY STORAGE MONITORING

Downhole pressure, temperature and vibration monitoring of gas (UGS), hydrogen energy (HES), and compressed-air energy (CAES) storage wells provide operators with the basis for accurate material balance, fluid level calculations and tubing stability. Governments are increasing regulatory demands for monitoring underground energy storage volume and pressure, and confirmation of caprock integrity on a frequent and long-term basis.

Acoustic Data’s SonicGauge™ Wireless Monitoring System allows cost-effective regulatory compliance by providing high-accuracy and high-resolution downhole data to identify the smallest deviation from expected subsurface storage pressure. The system can dynamically measure injection and production pressure gradients via the SonicRepeater stations equipped with onboard sensors deployed at strategic locations along the tubing string. Injection and production rates can be large and induce tubing oscillation, so in addition to providing pressure and temperature data, the technology can report highly sensitive vibration parameters in real-time, allowing the operator to safely manage injection and withdrawal rates.

The system can be retrofitted on slickline or e-line using the Barracuda™ HEX-Hanger™ (high expansion gauge hanger) in monitoring wells with tubing sizes from 2-3/8” to 13-3/8”, offering a rig-less deployment option. The technology can be set virtually anywhere in the tubing string by the battery-powered Electro-SET (electro-mechanical setting tool).

The SonicGauge functions on an ultra-low energy budget and can provide real-time data for up to eight years without well intervention, thus reducing operational expenditure and risk for years at a time.