RESERVOIR MONITORING

Permanent downhole monitoring systems allow engineers to observe reservoir performance at the click of a button from anywhere in the world rather than relying on short periods of planned testing. Engineers can quickly analyse pressure and temperature responses to changes in production, injection or lift rate, and identify production enhancement opportunities.

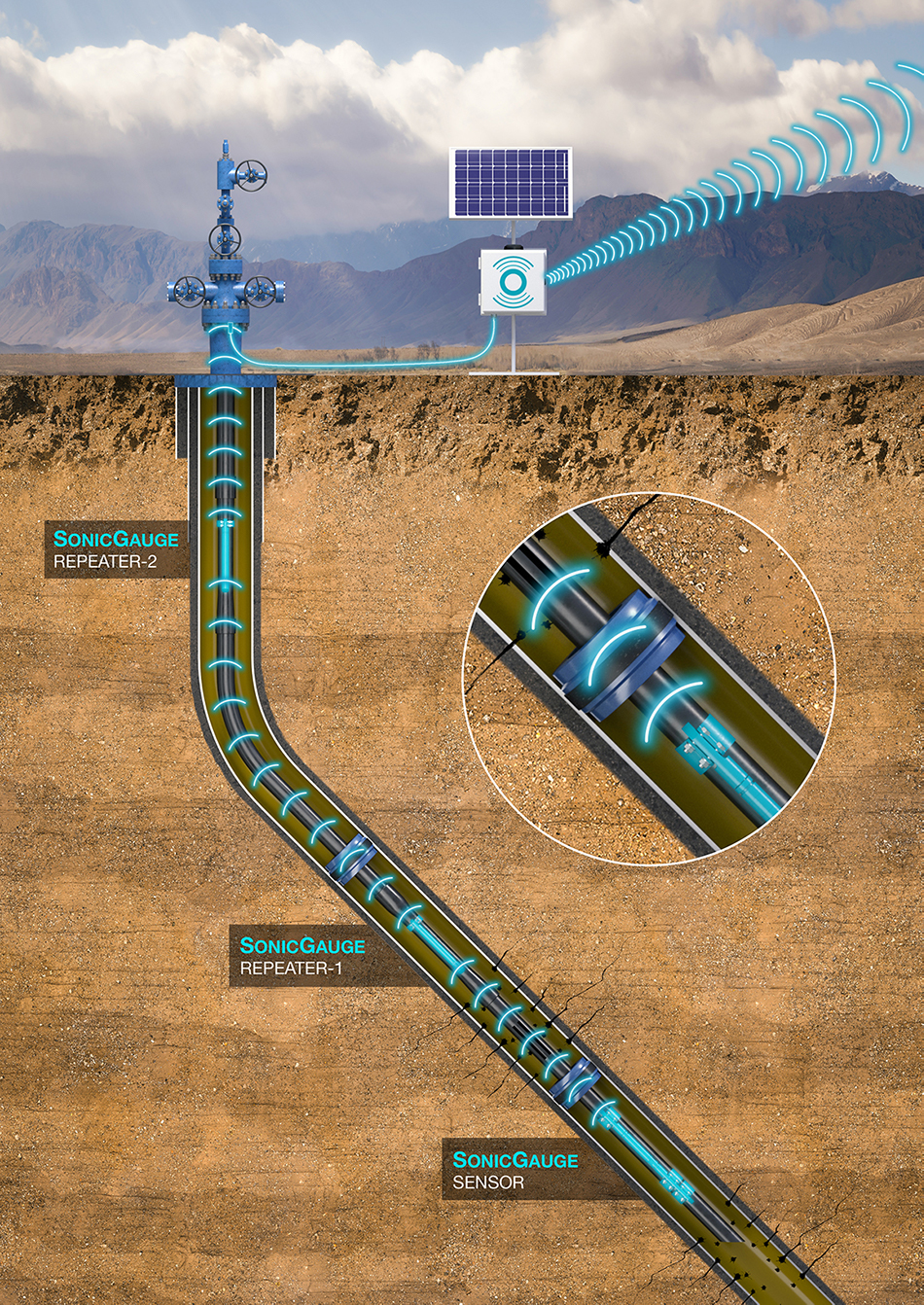

Acoustic Data’s SonicGauge™ Wireless Monitoring System offers simple and reliable real-time data acquisition and reporting as an alternative to both cabled permanent downhole gauges (PDHG) or infrequent memory gauge surveys. The technology can be permanently deployed on clamps or ported subs on the outside of tubing at the time of well completion, or it can be retrofitted inside the production tubing on the Barracuda™ HEX-Hanger™ (high expansion gauge hanger) via slickline or e-line.

The HEX-Hanger does not require a nipple profile, so the SonicGauge can be set virtually anywhere in the completion by the battery-powered Electro-SET™ (electro-mechanical setting tool). Additionally, SonicRepeater stations are equipped with onboard pressure transducers to report the well’s flowing and static pressure gradients in real-time.

The convenience of the Barracuda system also facilitates the use of the SonicGauge for short-to-mid-term extended well-testing operations. Equipment can be quickly deployed via well intervention, real-time data obtained, and retrieved for the next operation. The key benefit for these types of applications relates to real-time data improving operational efficiency through subsurface visibility, reducing well-test time.