PRODUCTION WELL TESTING

Well testing is performed to establish the Inflow Performance Relationship (IPR) and estimate tubing pressure and temperature gradients. The information gathered can be used to calculate permeability, estimate Skin and identify boundaries and barriers. Real-time surface monitoring of downhole pressure allows the operator to confirm Pressure Build-Up (PBU) stabilization and avoids the guesswork associated with memory gauge surveys. This guarantees data quality and avoids the unnecessary loss of production by enabling the well to be opened up sooner.

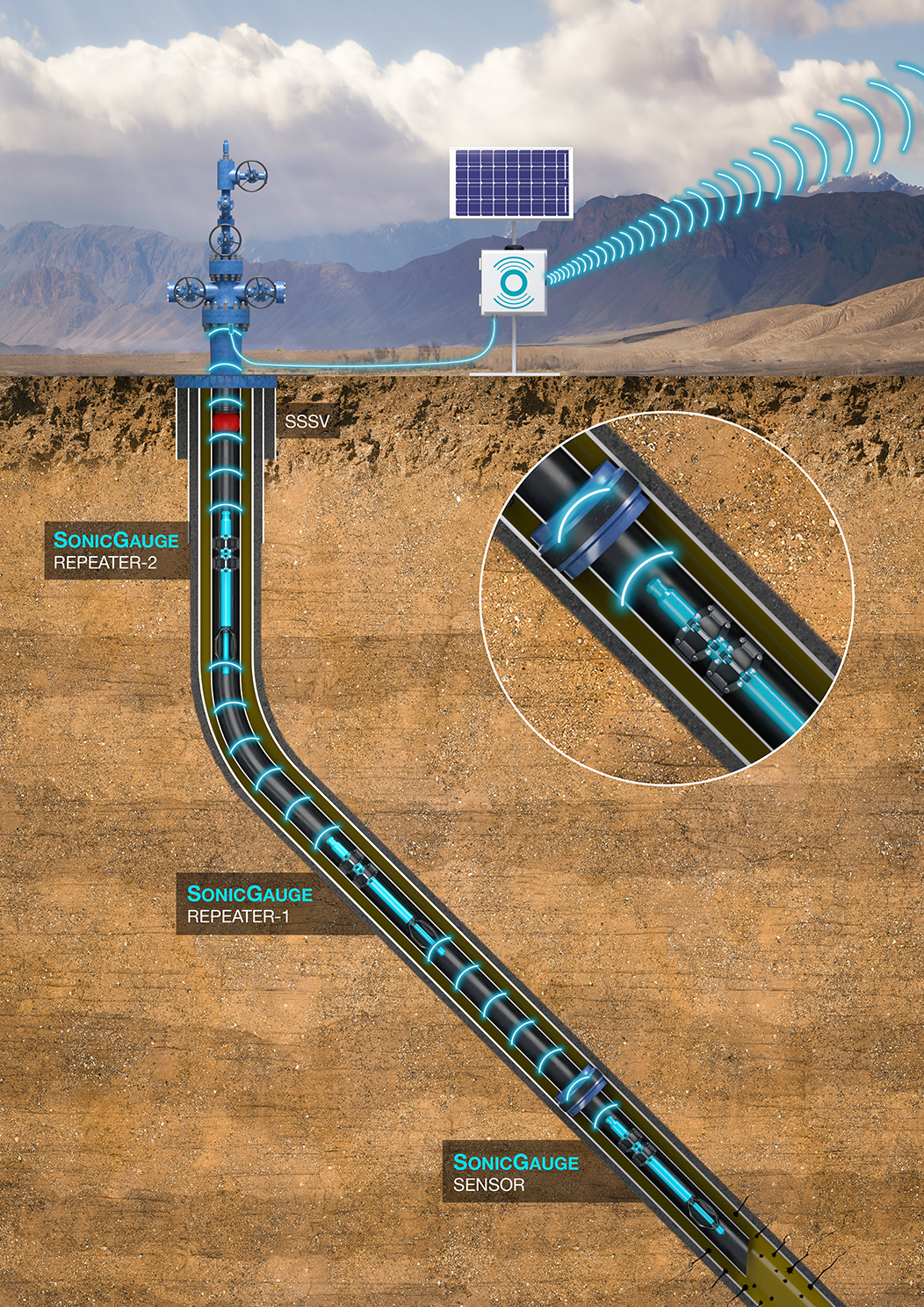

During well test flow periods, Acoustic Data’s SonicGauge™ Wireless Monitoring System allows real-time flowing bottom-hole pressure (FBHP) and pressure gradient points along the wellbore to be observed at surface. Because the SonicGauge can transmit data across barriers, incorporation with a downhole shut-in tool (DHSIT) allows PBUs to be conducted without wellbore storage effects whilst monitoring in real-time at surface.

The SonicGauge is installed at any depth in the tubing by the Barracuda™ HEX-Hanger™ (high expansion gauge hanger) via traditional slickline or e-line methods enabling a standalone solution for both downhole and surface systems. The HEX-Hanger has an ultra-slim profile (1.31” OD), providing minimal flow restriction but with an anchoring capability of over 2,000kg. The technology is set by the battery-powered Electro-SET™ (electro-mechanical setting tool).