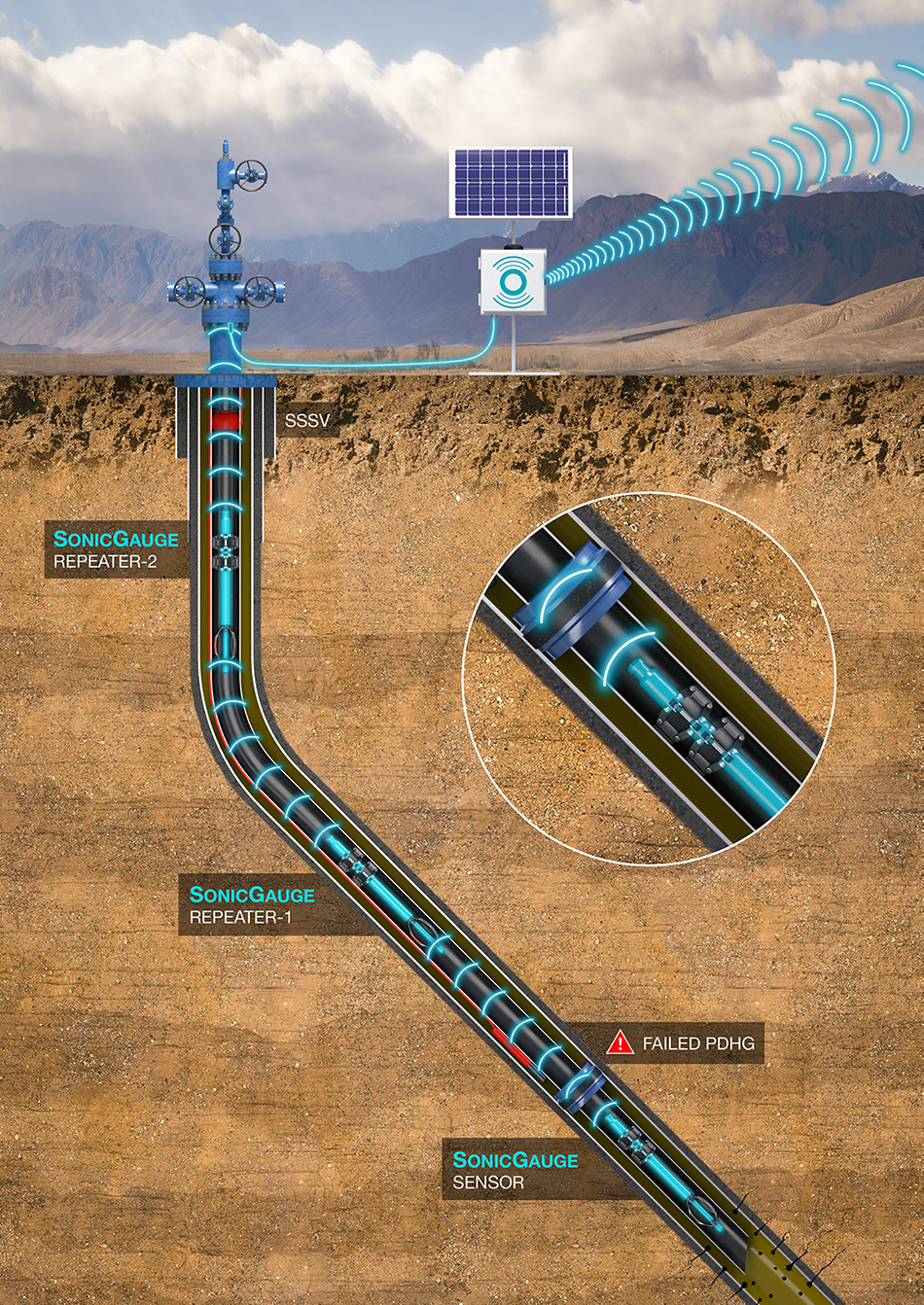

REPLACEMENT OF FAILED DOWNHOLE GAUGE (PDG)

Permanent downhole monitoring of pressure and temperature greatly improves the understanding of reservoir performance and production enhancement opportunities. Traditionally, this has been achieved with a cabled permanent downhole gauge (PDG), which provides real-time data at a specific depth.

The loss of PDG due to issues such as splicing errors, broken cabled connectors, grounding out, sensor failure or during well service activities can seriously impede an operator’s ability to monitor and optimise a well’s performance. Traditional remediation methods require a potentially costly well-intervention program, which is often un-economic or impractical when considering both service costs and loss of production.

Acoustic Data’s SonicGauge™ Wireless Monitoring System can be retrofitted into a well where a cabled PDG has failed or into new or brownfield developments where no monitoring was previously installed. The system has been designed to minimise installation costs with the Barracuda™ HEX-Hanger™ (high expansion gauge hanger) being installed via slickline or e-line methods. The HEX-Hanger does not require a nipple profile, so the SonicGauge can be set virtually anywhere in the completion by the battery-powered Electro-SET™ (electro-mechanical setting tool).

Unlike a cabled PDG that measures pressure and temperature at a single point in the tubing, SonicRepeater stations have onboard pressure transducers that allow the well’s flowing and static pressure gradients to be measured in real-time, an invaluable tool for real-time production optimisation.