DRILL STEM TESTING SRO

The Drill Stem Test (DST) plays a pivotal role in prospect evaluation and subsequent field development planning. Therefore, it is imperative to acquire reliable, high-accuracy downhole pressure and temperature data in a timely manner to allow the reservoir evaluation to be conducted without introducing additional uncertainty or delay.

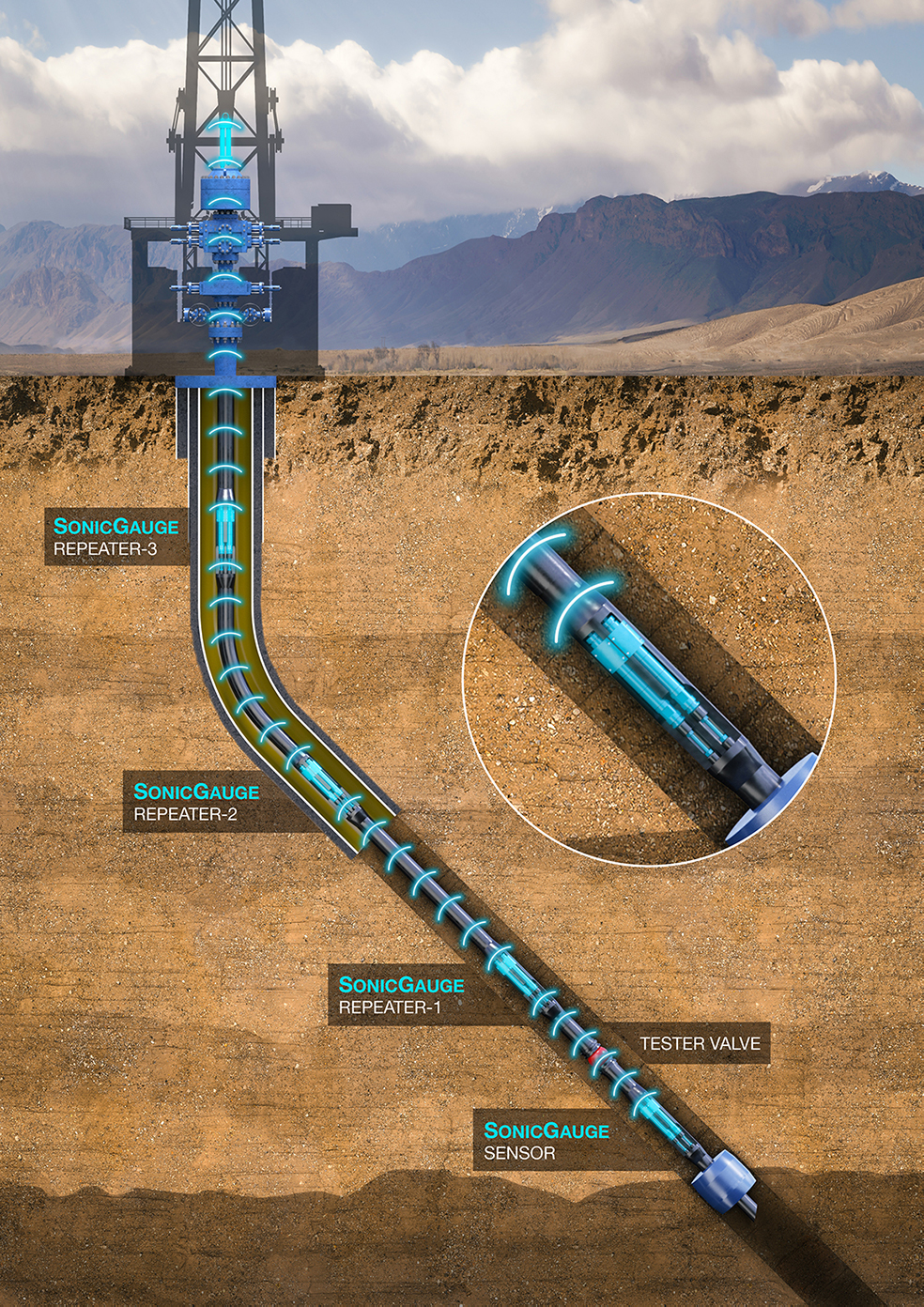

Acoustic Data’s SonicGauge™ Wireless Monitoring System delivers surface-read-out (SRO) of downhole pressure and temperature data in real-time via acoustic telemetry transmitted through the drill pipe. Access to real-time reservoir response data from below the tester valve allows live analysis of the well test, leading to fast and informed decision-making at wellsite or remotely via satellite or cellular communication. In turn, this decreases risk, rig time and lost production.

OTHER TECHNOLOGIES

The SonicSync™ Command+Control Platform can send wireless signals downhole to trigger Fluid Samplers at a click of a button.

The SonicAnalyst™ TCP & Frac Monitor provides positive confirmation and the exact time when perforation guns have been fired, which is particularly useful with phased perforating timing.