ARTIFICIAL LIFT MONITORING & OPTIMISATION

Artificial Lift Systems (ALS) need to be actively managed to optimise performance and ensure that they are delivering a positive return on investment through a production increase over a given period of time. Monitoring real-time reservoir pressure ensures that systems are run at optimal efficiency, extending maintenance intervals.

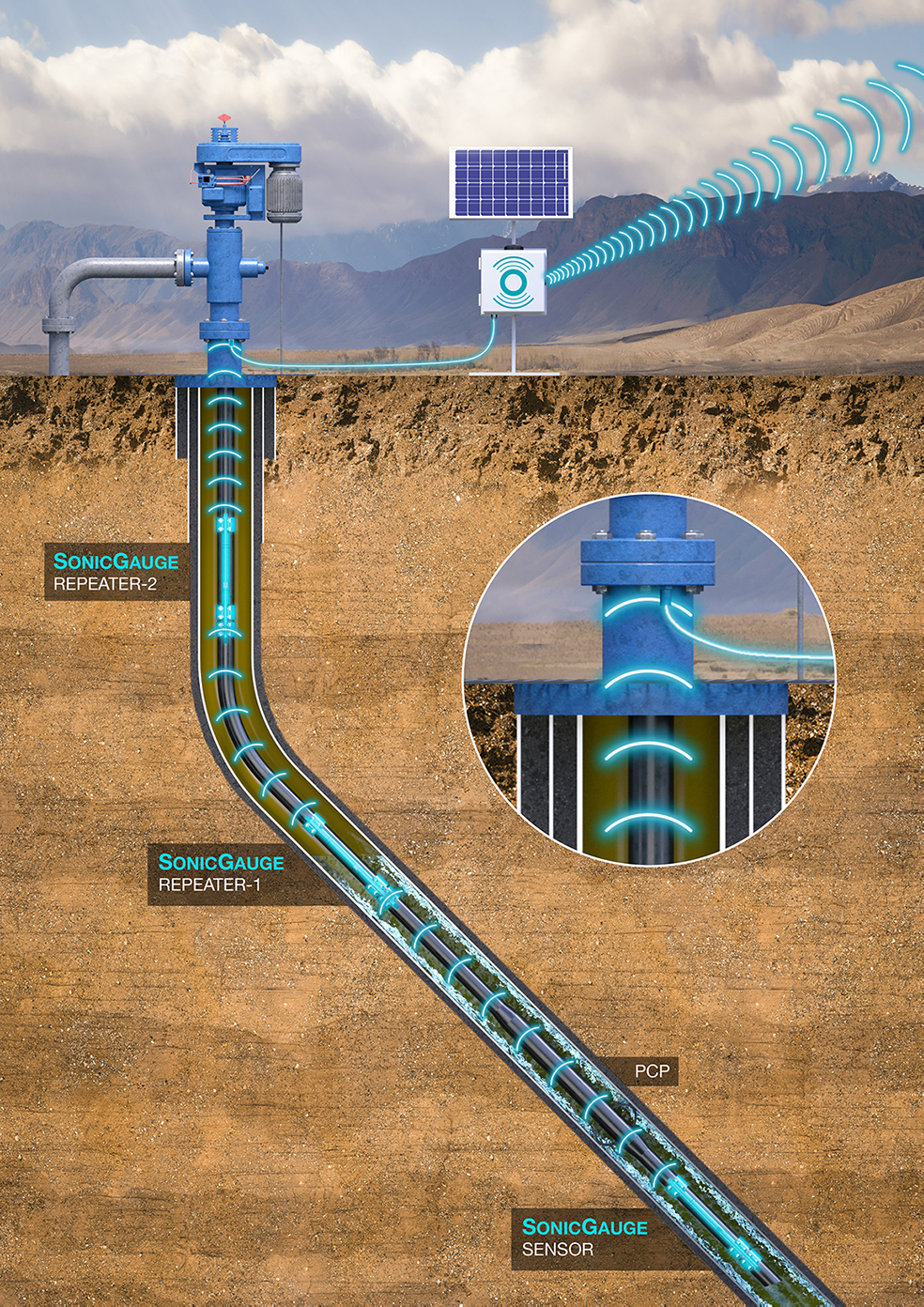

Acoustic Data’s SonicGauge™ Wireless Monitoring System offers a downhole solution that allows engineers to observe ALS operating efficiency in real-time. ALS operating parameters can then be adjusted promptly, increasing technical efficiency and production, and protecting the system from running at an undesirable operating point that could lead to damage or reduction of run life.

The cable-less (and snub-able) SonicGauge can be quickly installed offline before the production tubing is run-in-hole. It does not require wellhead penetration or packer pass-throughs and does not require the well to be killed when the tubing is pulled during workovers—a major technical advantage in applications such as Coal Seam Gas.

In the case of a well which uses Gas Lift or an Electrical Submersible Pump (ESP), and has a failed cabled downhole gauge, a SonicGauge System can be retrofitted via slickline to restore real-time data acquisition to optimise production performance. In the case of the ESP, a SonicGauge sensor can be installed in a Y-Tool to record and transmit intake data, and a second sensor can be located above the pump to record discharge data, which includes pressure, temperature and vibration.