SONICGAUGETM

WIRELESS MONITORING SYSTEM

- 170+ years of accumulated downhole monitoring time globally (350+ installations)

- Leading provider of wireless data acquisition for subsurface energy storage and O&G wells

- Covers the entire well lifecycle, from DST SRO to multi-year Production Optimisation

- Fully wireless: no wellhead penetrations, downhole cables, or connectors required

OVERVIEW

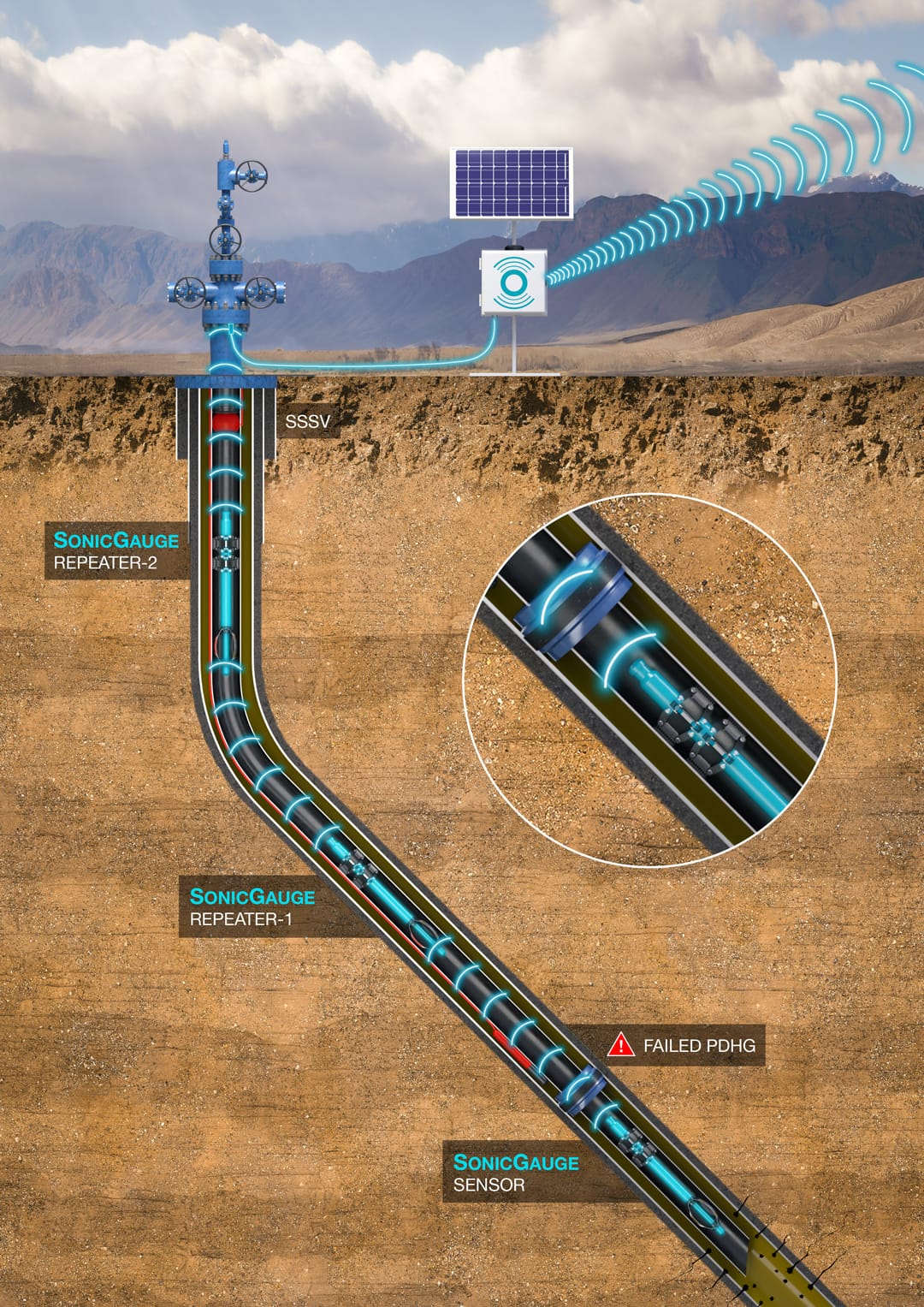

The patented SonicGauge™ Wireless Monitoring System is a two-way (duplex) acoustic telemetry system designed for high-frequency downhole data acquisition during DST and Well Testing programs while also being able to provide multi-year life for applications, such as Reservoir and Artificial Lift Monitoring. Uniquely, the technology has been proven to perform reliably during production, injection, and monitoring phases across the entire well lifecycle. There is no depth limitation, as SonicRepeater stations can boost the acoustic data packets to surface and acquire local data for gradient surveys and multi-zone monitoring. The downhole tools can be mounted on tubing or retrofitted by slickline, digital slickline and e-line.

APPLICATIONS

- Underground Energy Storage Monitoring ➔

- Underground CCS Monitoring (Coming Soon)

- Drill Stem Testing (SRO & Tool Activation) ➔

- Production & Extended Well Testing ➔

- Reservoir Monitoring ➔

- Artificial Lift Monitoring ➔

- Failed PDG Replacement (Retrofit) ➔

- Interference Observation Monitoring ➔

- P&A | Barrier Monitoring & Verification ➔

- Frac & Gravel Pack Monitoring (Coming Soon)

DEPLOYMENT OPTIONS

HIGH EXPANSION GAUGE HANGER (RETROFIT)

Our patented Barracuda™ HEX-Hanger™ is a high expansion gauge hanger that can be installed anywhere in tubing or casing via slickline, digital slickline or e-line. The technology was developed as a retrofit deployment option for our SonicGauge™ System in wells with no gauges or with a failed permanent downhole cabled gauge (PDHG).

GAUGE CARRIER & WASH PIPE CARRIER

The external gauge carrier and internal wash pipe carrier provide a high degree of protection for the SonicGauge™ sensors. This installation option is generally used in drill stem testing, frac pack, and gravel pack applications. For permanent monitoring installations, we would recommend a more compact welded pup joint. The carrier and the pup-joint can be ported to annulus or tubing as required.

TUBING CLAMPS

External clamps are used to deploy SonicGauge™ sensors monitoring the annulus and for SonicRepeater stations used to boost the acoustic data packets to the surface. The SonicGauge and SonicRepeaters are clamped to the tubing at pre-determined intervals along the string. Installation takes minutes and can be carried out offline.

SUSPENDED BELOW PLUGS & PACKERS

The SonicGauge™ can be run directly below a bridge plug, storm packer, inflatable packer, etc., to monitor and transmit real-time pressure at the setting depth for barrier verification purposes. Please view the SonicGauge™ Barrier Verification System for more information relating to this application.

SIDE POCKET MANDREL

For operators requiring real-time data at surface but requiring a completely clear and accessible wellbore, we have developed and patented a bespoke latch to deploy our SonicGauge™ in a side pocket mandrel (SPM). The SonicGauge is run on slickline with a kick-over tool and set in a custom-length SPM. Individual tools may be retrieved as required for battery change and on-board data download.

SURFACE OPTIONS

SOLAR POWER MODULE

Fully independent and compact system using solar energy to power the SonicGauge™ Data Logger (SDL).

MODBUS / SCADA

Downhole data can be routed to your desktop via a Modbus interface that connects to your remote terminal unit (RTU) at well site, providing a complete 'Downhole to Desktop' solution.

3G/4G-WIFI MODULE

This module can be connected to an operator's network directly or via a secure VPN tunnel. For smaller clients, the VPN server can be hosted by Acoustic Data as a cloud solution. The SonicGauge™ Data Logger (SDL) is enabled to receive over-the-air (OTA) firmware updates and transmit real-time downhole data without the need for a remote terminal unit or physical intervention.

EXD ENCLOSURE

For hazardous zone deployments, we offer a Zone 1 rated EXD Enclosure and Solar Power Module solution.

ANTI-THEFT / VANDAL MODULE

For locations where theft or vandalism of surface equipment is a concern, we offer secure armoured vaults or secure subterranean modules for installation at the wellsite. Please enquire for tailoring a system to your requirements.

SUBSEA INTERFACE

The SonicGauge™ Data Logger (SDL) is being integrated into an industry-leading Subsea System for multi-year data acquisition. For more information, please contact our team.

SPECIFICATIONS

| SONICGAUGE™ WIRELESS MONITORING SYSTEM | |

|---|---|

| Real-Time Surface Read-Out (SRO) | Yes (1 Second to Hourly Data) |

| Communication Type | Duplex via SonicSync™ (Two-Way Mesh Network) |

| Transmission Distance | Unlimited with SonicRepeater Stations |

| Downhole Sensor | Piezo | Quartz |

| Multi-Sensor Configuration | Optional |

| Temperature Rating (Max.) | 150°C (302°F) |

| Pressure Rating Options (Max.) | 10,000 | 15,000 | 25,000psi |

| Length | 1,300 – 1,800mm (51.2" - 70.9") |

| Diameter | 33.4mm (1.31") |

| Material | Super Duplex | Inconel |

| Battery Life | Up to 8 Years (20% Safety Factor) |

CONTACT US

Have a question or want to book a demo?Our team of experts are on hand to help.